Sustainable Aero Lab: A Global Accelerator for the Future of Flight

Since 2021, nearly 100 sustainable aviation companies have been mentored in the program, with numerous cooperations and investments made.

35 alumni

120 startups mentored

30+ cooperations & partnerships made

Graduated Startups at the Sustainable Aero Lab

-

Aeroflexure is developing a new type of Morphing Wing technology for the aeronautical industry. Morphing Wing systems allow new and old airplanes (retrofitting) to modify the wing shape in flight. This system can improve the aircraft's aerodynamics, helping to reduce the fuel burn by up to 10% while decreasing the noise levels by about 10 dB during takeoff and landing. This solution also uses the existing aileron or flaps actuating system for seamless integration into the wing structure.

First eSTOL designed for regional cargo and passenger travel

-

Airflow's airplane is designed to operate from runways as short as 50 m (in proximity or even from the roof of factories and distribution centres) with a payload of 225 kg plus 1 pilot, on ranges around 400 km. Ultimately the aircraft would offer 1/3 of the hourly operating cost of a helicopter or eVTOL.

In 2022, Airflow was acquired by Electra.aero.

Drone service for autonomous long-distance inspection

-

The company provides long-range inspection flights with a Drone-As-A-Service business model.

This approach integrates aircraft development, production, certification and operation under one single entity. Customers (e.g. operators of pipelines and powerlines) can order imagery and data regarding the status of their assets at certain geolocation, without worrying about technical and legal feasibility as well as drone operation and maintenance.

Integrated ducted fan modules for electric aviation

-

Blue Bear has pioneered the Integrated Propulsion Module (IPM), an electric propulsion architecture that integrates energy storage and thrust generation.

The IPM uses a ducted fan architecture to offer scalable, modular, safe, efficient, and quiet propulsion solutions for UAS, eVTOL and eCTOL aircraft, enabling sustainable transportation of goods and passengers.

Low-weight passive heat management and cooling

-

Calyos' core technology is passive cooling by Loop Heat Pipes (LHP). This solution improves performance while providing considerably more design flexibility than traditional heat pipes. In aircraft, the key applications are for converters/inverters, batteries, fuel cells and other embedded electronics.

Calyos' systems offer an alternative to active water cooling systems, removing the need for pumps, and so reducing weight, maintenance and energy consumption.

LHP tech also allows recovering waste heat for using it in other applications such as de-icing or pre-heating.

Electric aircraft conversion for thin-haul routes

-

Dovetail aims to develop, integrate and commercialize electric aircraft powertrains and airplanes.

• Retrofitting existing small passenger aircrafts into electric to make thin haul routes sustainable.

• Developing a brand-new electric aircraft with Distributed Electric Propulsion designed to maximize the benefits or electrification for the regional thin haul market (19-passengers and 900 km range).

Fast detection of flaws & damages in carbon fibre composites

-

Eddytec's solution offers automated measurement of cracks and delaminations by means of an induction sensor array.

Composites based on carbon fibres (CFRP) contribute to decarbonising aviation by enabling lighter, more fuel-efficient aircraft. However, their quality assurance and maintenance involve time-consuming visual and ultrasound inspections. Eddytech simplifies the process, allowing a 90% reduction in measurement time.

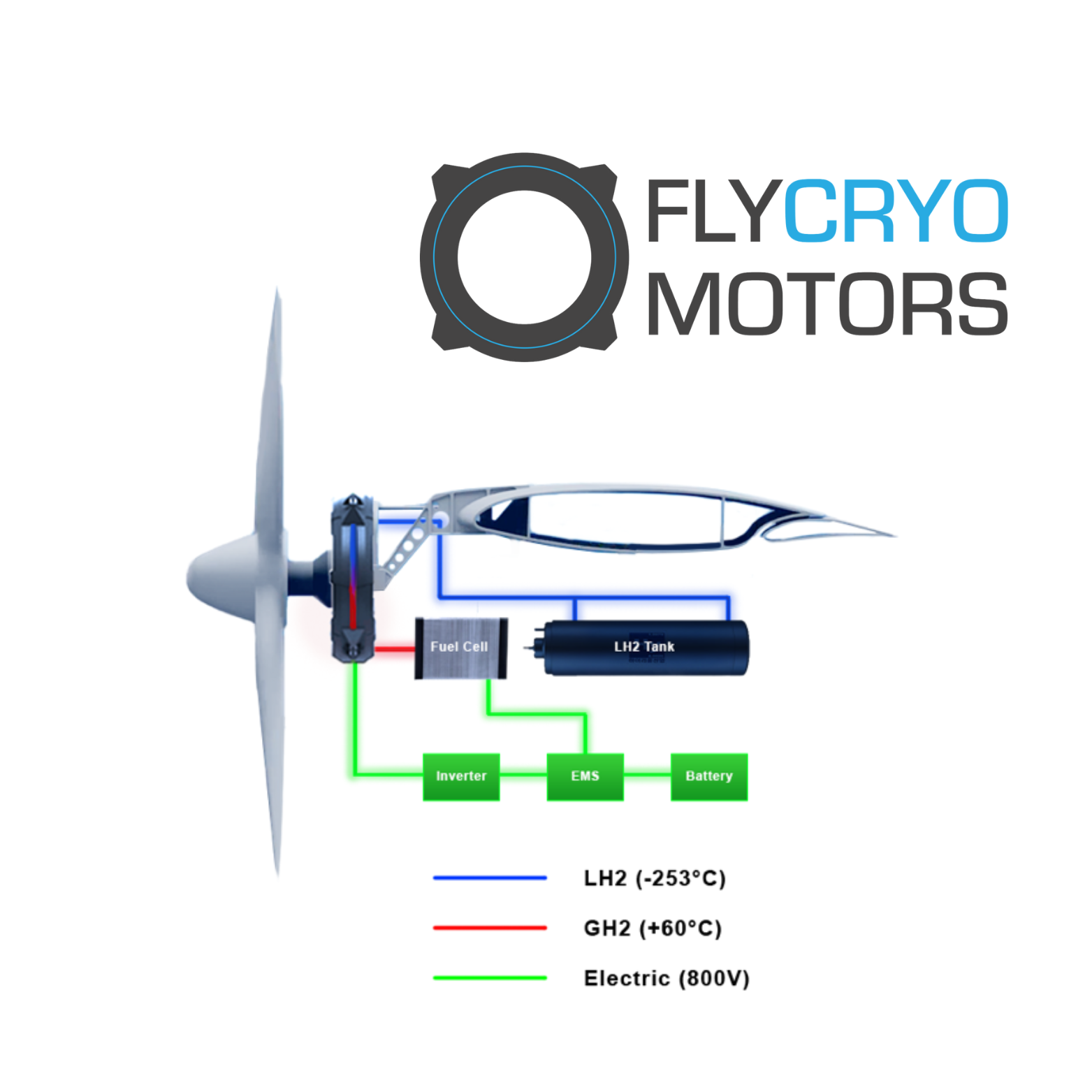

Annular shaped electric motor, cryocooled by LH2

-

FlyCryoMotors develops an LH2 cryocooled electric motor.

Its motor uses an axial flux architecture and is cooled through the liquid hydrogen used in the connected fuel cell system. Cryogenic conditions are created inside the winding coils, shaped as hollow tubes, in which the liquid hydrogen flows through, extracting the heat. The extreme cooling enabled by this technology allows an aircraft to fly with a 200% overboost performance during takeoff and climb.

Low-cost on-demand airline for sustainable regional air travel

-

Flyvbird provides sustainable on-demand regional air travel services, connecting underserved rural and regional airports. Leveraging AI algorithms and low-emission aircraft, Flyvbird delivers flexible, customer-centric scheduling while minimizing environmental impact.

The company plans to launch services in 2025 using the Tecnam P2012 aircraft. Later, Flyvbird will shift to a fleet of nine-seat electric aircraft from U.S. startups Eviation and Electra.aero, transitioning into a fully electric regional airline.

Blended-Wing-Body extremely-efficient remotely-piloted aircraft

GRADEL Robotic Additive Manufacturing (GRAM)

-

Getwing’s Blended-Wing-Body cargo drone delivers extreme operational efficiency through remote piloting and electric propulsion.

Traditional feeder aircraft transporting cargo between small airports and hubs face high fuel consumption, maintenance costs, and pilot shortages. Getwing’s eco-friendly, battery-powered drone addresses these challenges with a 1,000 kg payload and 50% lower drag than conventional designs. Its remotely piloted system enables a single operator to control multiple aircraft, significantly reducing operational costs while enhancing scalability.

-

This Gradel’s robotic additive manufacturing technology is able to offer ultra-lightweight structures decreasing energy consumption and CO2 emissions while improving resource efficiency and sustainability by introducing bio-based and recyclable raw materials.

Gradel secures funds for bringing their robotic system to become intelligent and autonomous in collaboration with Data Design Engineering. And additionally, working on pre-qualification for space applications in collaboration with ESA, Airbus D&S, OHB Systems, and Thales Alenia Space under the supervision of the Luxembourg Space Agency.

-

HyFlux is developing a zero-emissions powertrain enabled by superconducting motors, cooled by Liquid Hydrogen, for hydrogen powered aircraft.

The solution relies on high temperature superconducting (HTS) and optimisation of the configuration of motors to meet aerospace light-weighting, highly efficient drive for multi propellor aircraft, from eVTOLs to single aisle in a modular package.

HyFlux engages along the entire development chain related to the use of liquid cryogenic hydrogen for aviation propulsion.

Ultra efficient cryogenic electric-hydrogen drivetrain

Very light and efficient electric motors for longer range flight

-

Kite Magnetics is producing a new generation of lighter (up to 50%) and more efficient electric motors, that enable aircraft to fly further (up to 15% additional range on regional aircraft) and transport heavier payloads.

This novel propulsion tech is based on a new nanocrystalline magnetic material boosting the highest saturation magnetic polarization among nanocrystalline alloys, while still offering core losses that are 10x smaller than equivalent materials used in motors today.

Hybrid-electric engines with superior economics

Direct window-to-window delivery drones

-

The company is developing a range of hybrid electric-combustion engines for aircraft propulsion, combining turboprop engines and piston engines with electric motors.

Two-in-one engine concept for safe operation also for single-engine aircraft. Power output from 500 to 2,400 SHP. Applications range from regional and general aviation to rotorcraft. The technology allows to save up to 60% on the engine price and 40% on fuel consumption.

-

Maple pioneers an AI-powered autonomous electric window-to-window delivery drones. Maple's drones can autonomously pick up and deliver goods at plug-and-play windows-installed adapters, enabling fast transportation while delivering significant cost and time savings with enhanced operational efficiency.

This solution eliminates the need for complex infrastructures, trained staff and lengthy approvals. The bridgehead market is critical medical supplies for hospitals and healthcare providers. At a later stage, reshaping urban logistics across e-commerce, food and grocery delivery, parcel services, and industrial goods.

The venture plans to deploy drone ports across cities functioning like car charging stations.

Software & infrastructure for rapid development, testing of air vehicles.

Clean-sheet electric aircraft for affordable regional mobility

-

With Marpin Labs, OEMs can unlock value, boost productivity, and save man-years and millions of dollars in R&D, I&T, and certification. Their next-generation CloudTS platform gives OEM teams super-powers by enabling seamless collaboration workflows between data acquisition instrumentation, flight test, and flight sciences teams.

CloudTS offers a data-centric, software-first, and software-defined solutions to the challenges faced in systems engineering, integration and test, data management, real-time monitoring, and scalable machine performance analysis.

-

MD Aircraft is developing the MDA1 EViator, a clean-sheet, highly efficient 10-seat electric aircraft designed for straightforward EASA certification. The initial propulsion system will be fully electric, with the option to incorporate SAF-powered ICE range extenders in later variants. The aircraft family is planned to scale up to 30-seat and 80-seat configurations.

The MDA1 EViator aims to enable zero-emission regional flights by 2030, operating at significantly lower costs compared to conventional combustion-powered aircraft. The company is already collecting a growing number of Letters of Intent (LoIs), and a site for future series production has been identified.

-

Mobius is producing battery module optimized for electric aircraft propulsion that can be cost-efficiently repurposed.

It possesses a high energy density, fast charging, rapid cooling, and a high cell-to-pack mass ratio of >0.8, enabled by a novel lightweight superthermal conductor (STC), which prevents thermal runaway through rapid heat dissipation. Mobius’ business model brings together battery subscription, maintenance, and salvage service, including the second life repurpose and the end-of-life recycling so to enable the circular economy.

-

MUUV's uncrewed cargo plane is equipped with a plug-in hybrid-electric powertrain that blends the efficiency of electric propulsion with the range of traditional fuels. The ICE extender allows a range four times longer than flying solely on batteries.

Aimed for quickly moving critical items and preventing downtime for industries such as energy and natural resources, agriculture, defence and disaster relief, as well as middle-mile cargo.

-

The company develops a cloud-based AI-powered software platform for fleet management aimed at optimising the scheduling, dispatching and routing (utilization) of ground-handling vehicles. Moonware’s software platform makes use of machine learning and sensor fusion to minimize delays due to the uncoordinated and untracked handling practices currently in use, reducing human-induced accidents involving ramp damage to aircraft or terminal buildings, and the unnecessary fuel consumption associated with taxiing aircraft to and from the runway. These measures could result in approximately $30B+ in global savings every year.

A smart autonomous ecosystem for ground operations at airports

SaaS optimization services for the aviation industry

-

Motulus provides SaaS optimization services to the aviation industry. Based principally in Antwerp, the company has deep routes in mathematics and software development. These core competencies have been combined to develop three core products:

- Integrated crew planning (the planning of flights and standby to crew)

- Tail assignment (the allocation of aircraft to flights and engineering slots)

- Network design (planning an airline schedule: considering revenue opportunities and costs)

-

Pattern Labs is building an autonomous system for airport baggage and cargo logistics. Its software connects bag manifests, flight arrival/departure times, gate locations, staffing schedules, and aircraft ADS-B position data to optimize the work of a hybrid robot/tug fleet. The startup also develops the related robotic vehicle.

Pattern Labs building an efficient robotic solution is the fastest way to realize electric equipment adoption in this sector and can lower emissions in airport operations.

Autonomous robots for airport baggage and cargo logistics

A novel jet engine that is simpler, lighter, and cost efficient

-

A conventional turbofan has up to 18 compressor and 8 turbine stages. In this concept, the fan is driven by the hot gas, blown out of its trailing edges, thus replacing the turbine.

The concept appears most suitable for replacing small turbojets but with an efficiency typical ofturbofans and with a lower engine weight.

The expected reduction in fuel consumption respect to a turbojet of the same thrust class is 33%. At the same time, the engine is expected to offer a reduction ~20% in manufacturing costs and ~40% in maintenance costs compared to turbofans.

The smallest magnetic passive sensor in the world

-

RVmagnetics developed the smallest multipurpose magnetic passive contactless sensor based on MicroWire, using one single infrastructure, principle and logic.

These miniaturized (⌀ ca. 3–70 µm) sensors can measure physical quantities such as pressure, temperature, flow, vibrations, etc. Their size, robustness, simple production, chemical resistance, and wireless capabilities make them suitable for a wide range of aircraft applications, such as monitoring propulsion, systems, structural health, and smart materials.

Predictive ATC system to reduce delays, fuel burn and emissions

-

The company is developing an Air traffic management solution aimed at creating better predictability so to reduce aircraft holding at congested airports, and hence decreasing flight delays, airline operational costs and emissions.

SASI’s Smartlot allows an airplane to reserve a landing slot just minutes from its takeoff, way before approaching its destination airport. This way the average time wasted by airliners loitering around airports, waiting for their landing slot, can be reduced by at least 50%.

This implies saving a minimum of €100/reduced flight minute for the airlines and so decreasing aircraft CO2 emissions by a minimum of 30% during the flight landing phase.

Sustainable & affordable e-fuels for sustainable aviation

-

Spark e-Fuels develops and operates a decentralized production network of facilities supplying e-crude and sustainable aviation fuels cost-effectively and at scale. Its technology is based on fully-integrated, modular end-to-end e-fuels plants capable of significant Capex and Opex gains.

The aim is to produce a crude oil-like e-crude, upgraded to SAF in a co-refining process with established refineries and then supplied to airlines.

Spark addresses the main hurdles of e-fuels: high cost, low availability, and low sustainability, with an end-to-end process, based on a total value chain design focused on location-tailored refining solutions.

Electric flying vehicles boosting lowest cost per mile

-

Speeder Systems is developing an efficient electric flying vehicle aimed at offering the lowest cost per mile. Speeders combine VTOL and ground effect technologies to maximize speed (max 200 km/h) and range (110 km to 150 km) with a cargo capacity of 20-25 kg.

The technology is 20-40% more efficient compared to unmanned helicopters or quadcopters in high-flying mode and is 3x cheaper than a manned helicopter. These vehicles can reduce offshore cargo operational emissions up to 100x.

Electric, plasma-based jet engines

Passive radar boosting airspace safety and security

-

Sylphaero pioneers electric, plasma-based jet engines for clean aircraft propulsion. This technology is capable of reaching speeds way in excess of 1,000 km/h with the similar overall efficiency of electromagnetic motors but with a higher specific power.

The cost to design, manufacture, and operate this technology is significantly lower than fuel-based jets while maintaining a higher overall efficiency of around 60% compared to 40% for fuel-based jets. This technology can extend the applicability of electric propulsion to flight speeds way higher than feasible with present propeller- and fan-based systems.

-

An Advanced Passive Bi-static Radar system detects and tracks drone and bird threats in real time. The PRIMUS uses existing electromagnetic signals (e.g., TV and radio electromagnetic waves), AI-integrated algorithms and a modular design to provide a scalable, environmentally friendly, cost-effective solution.

Syncretise responds to the increasingly pressing demand for the airspace safety and security of airports, critical infrastructure, correctional facilities, vertiports, and urban spaces while minimising environmental impact, operational costs, and complexity, as well as increasing effectiveness in urban areas or adverse weather conditions.

Clean and affordable air mobility by electric planes

-

Vaeridion develops small, full-electric miniliners for affordable and sustainable air transportation. It is a 9-seat battery-powered airplane with advanced aerodynamics and maximum energy efficiency for ranges up to 500 km while using presently available battery and propulsion tech.

Its high aspect ratio wing provides minimum cruise drag and a high glide ratio. To optimize the structural weight and, therefore, the travel distance even more, the company integrates batteries into the wing, not into the fuselage.

Battery modules with unparalleled safety and durability

-

Volinergy is developing a battery module that increases flight time by 20%, ensures a lifespan 4x longer and grants higher safety from fire risks

The battery module features an innovative structure and a thermal management system, which enables an effective cooling of each cell while mitigating thermal runaway propagation between cells. The structure is composed of a unique material lamination making the battery module waterproof and fireproof.

This battery system can save up to 1300 kg CO2 eq per year per vehicle. In addition, the product's longer lifespan decreased the necessity for rare and highly polluting materials.

Gliders for airspeed logistics at ground transport cost

Morphing Wing for the aircraft industry

-

Aerolane offers a dual-use automated cargo glider, promising airspeed logistics at ground cost. The Aerocart approach can slash operational costs by 65% through decreasing fuel consumption, maintenance, and pilot requirements while also delivering a scalable, sustainable logistics solution and doubling the payload of existing aircraft.

Aerolane aims to reduce emissions by 60 million tons CO2 annually, aligning with the aviation sector's 2050 net-zero ambitions.

Low-cost sustainable hydrogen through Plasma-Catalytic Hydrogen Sulfide Methane Reforming.

Safe flight control system for autonomous drone flights

-

Fusion Engineering develops control systems for autonomous flight (drones), which are based on control algorithms implementing accurate positioning, disturbance rejection, and fault-tolerance able to substantially increase the safety of autonomous flight operations.

Fusion’s flight control algorithms are based on the novel INDI (Incremental Non-linear Dynamic Inversion) technology, developed at the Delft University of Technology (TU Delft) and are implemented in an isolated modular software architecture.

-

GERAD is transforming hydrogen production with its innovative Plasma-Catalytic Hydrogen Sulfide Methane Reforming technology. By converting methane and hydrogen sulfide into emission-free hydrogen and high-value byproducts, GERAD eliminates CO₂ emissions while enhancing efficiency. Their breakthrough approach significantly reduces production costs by leveraging low-cost waste feedstocks and addressing challenges like catalyst deactivation. With its potential to reshape the hydrogen market, GERAD is paving the way for a more sustainable and cost-effective energy future.

Safe, high-power battery modules for electric aircraft

Hybrid-electric aircraft offering unprecedented efficiency in air logistics

Shielded flat cables for sustainable aviation

Stratospheric quasi-geostationary airship for Earth sensing

-

New Cable Corporation reduces the weight of the electrical cable harness by up to 90% compared to similarly performing round cable harnesses. NCC's objective is to replace traditional round cables on regional and intercontinental aircraft, enabling lower transportation costs and faster assembly as well as lower material and energy consumption.

The NCC aims to secure a prime position in aviation cable solutions by 2030 while supplying solutions that reduce environmental impact, thus supporting aviation green transition.

-

Exploiting high-altitude winds to move upwind or crosswind like flying sailboats, O-BOOT airships are aimed at Earth sensing, environment monitoring (wildfires, forestry, pollution, etc.), reconnaissance, and communication.

O-boot's technology doesn't consume or pollute to keep position at about 20,000 meters altitude.

It can replace low-heart orbit satellites, where more flexibility and resolution are required, and high-altitude drones with a type of platform that is inherently way more sustainable and offers incomparably superior persistence.